Nickel-plated alloy equipment production line,Nickel-plated equipment manufacturer

Company:

Leimeng (Changzhou) Equipment Co., Ltd

Keywords:

Nickel-plated alloy equipment production line,Nickel-plated equipment manufacturer

Leimeng (Changzhou) Equipment Co., Ltd

Nickel-plated alloy equipment production line,Nickel-plated equipment manufacturer

Nickel plating equipment production line is a kind of automatic production line specialized in the production of nickel plated alloy products. This kind of production line usually integrates several process links such as plating, cleaning, drying, etc., which can efficiently and stably complete the processing task of nickel-plated alloy products.

I. Composition of the Production Line

The production line of nickel-plated alloy equipment is mainly composed of the following parts:

1. Pre-treatment equipment: including oil removal, rust removal, activation and other process equipment, used for surface treatment of the workpiece to improve the bonding between the plating layer and the substrate.

2. Electroplating tank: Electroplating tank is the core equipment of nickel alloy plating production line, which is equipped with nickel alloy plating solution inside. The workpieces in the plating tank will pass through the action of electric current, so that the nickel ions in the plating solution will be deposited on the surface of the workpieces to form the plating layer.

3. Cleaning equipment: It is used to clean the workpiece after plating to remove the residual plating solution and impurities on the surface to ensure the quality of the plating layer.

4. Drying equipment: Dry the workpiece after cleaning to prevent moisture from corroding the plating layer or affecting the appearance quality of the plating layer.

II. Working Principle

The working principle of nickel plating alloy equipment production line is mainly to realize the deposition of plating layer by electrochemical reaction. In the electroplating process, the workpiece acts as the cathode, and the nickel ions in the plating solution move to the cathode under the action of electric field, and get electrons on the surface of the workpiece, and then reduce to metallic nickel, which is deposited on the surface of the workpiece to form the plating layer. At the same time, other components in the plating solution also participate in the reaction to form a nickel-plated alloy layer with specific properties.

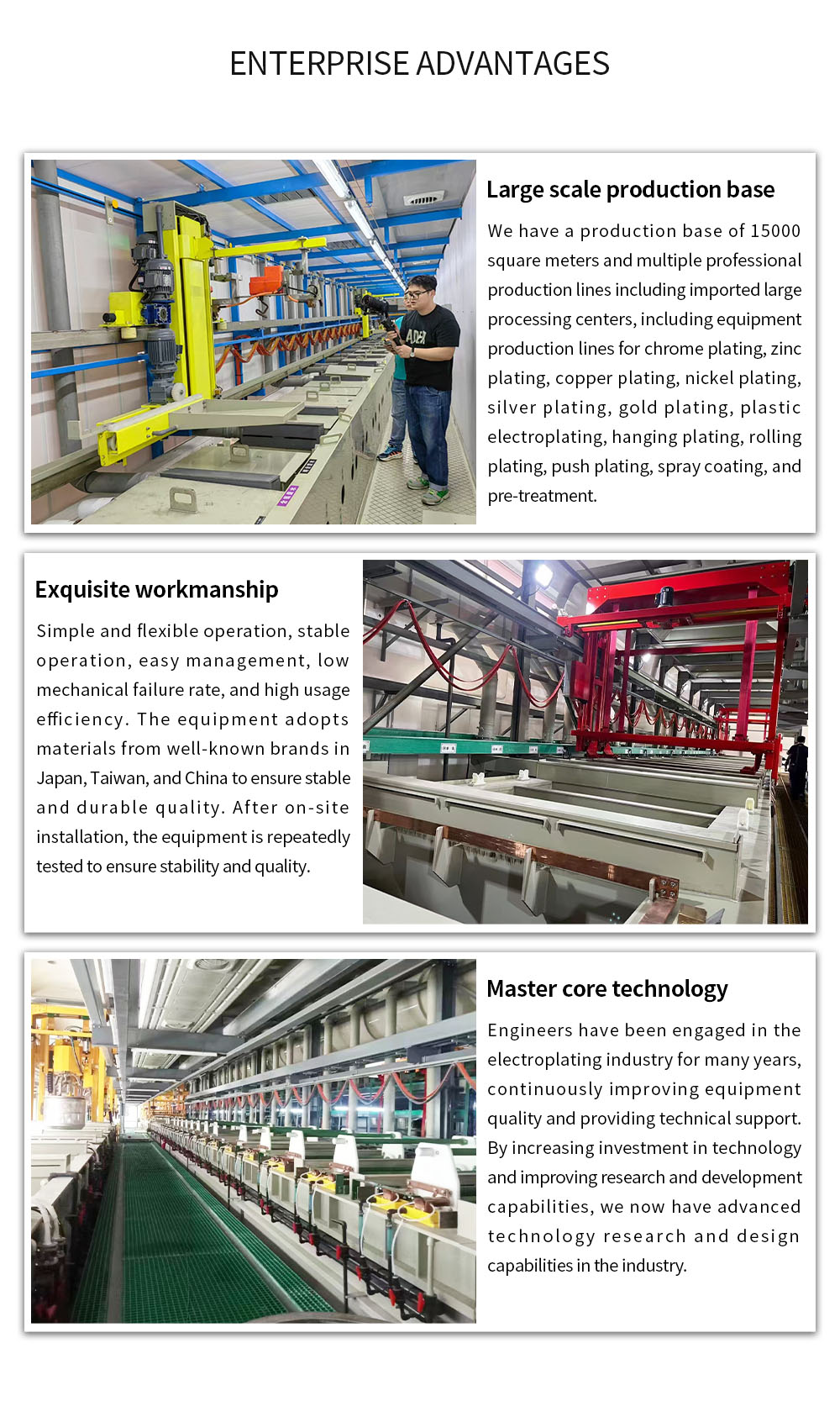

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.