Equipment introduction

Raymond Suspension Chain Oven Equipment - Industrial Drying Solutions

Raymond Suspension Chain Oven Equipment

Industrial Drying Solutions · Efficient Curing · Advanced Thermal Processing

Product Introduction

The Raymond Suspension Chain Oven Equipment is a state-of-the-art industrial drying and curing solution designed for continuous thermal processing of coated parts and components. This advanced system utilizes a suspension chain conveyor to transport products through precisely controlled temperature zones, ensuring optimal curing, drying, and heat treatment results. Our equipment is essential for powder coating, liquid paint curing, adhesive bonding, and various thermal processing applications across automotive, appliance, furniture, and general manufacturing industries where consistent, high-quality thermal processing is critical for product performance and durability.

At Raymond, we integrate global best practices and innovative technologies from leading manufacturers in Europe, USA, Japan, and Korea to deliver superior suspension chain oven solutions. Our equipment is engineered for optimal performance, energy efficiency, and reliability, featuring precise temperature control, uniform heat distribution, and advanced automation systems. We focus on providing systems that not only achieve exceptional processing quality but also minimize energy consumption, reduce operational costs, and ensure compliance with stringent environmental and safety standards. Partner with Raymond for a robust and efficient suspension chain oven solution that enhances your production capabilities and strengthens your competitive position in thermal processing applications.

Core Advantages of Raymond Suspension Chain Oven Equipment

- Continuous Processing Capability: Suspension chain conveyor system enables continuous, high-throughput processing of parts, maximizing production efficiency and reducing cycle times.

- Precise Temperature Control: Advanced multi-zone temperature control systems ensure optimal curing conditions and consistent processing results across all product types.

- Uniform Heat Distribution: Engineered airflow systems and heat distribution mechanisms provide uniform temperature throughout the oven chamber, eliminating hot spots and ensuring consistent quality.

- Flexible Part Handling: Suspension chain system accommodates a wide variety of part sizes, shapes, and weights, providing maximum flexibility for diverse production requirements.

- Energy Efficient Design: Advanced insulation, heat recovery systems, and optimized burner technology minimize energy consumption and reduce operational costs.

- Automated Process Control: Integrated PLC and HMI systems provide real-time monitoring and precise control of all critical parameters, ensuring consistent quality and operational efficiency.

- Environmental Compliance: Features advanced emission control systems, thermal oxidizers, and energy recovery to meet stringent environmental regulations.

- Comprehensive Safety Features: Incorporates advanced safety systems including fire suppression, emergency shutdown, and operator protection measures.

Process Flow

The Raymond Suspension Chain Oven Equipment employs a systematic multi-zone thermal processing approach to achieve optimal curing and drying results.

1

Part Loading

Coated parts are loaded onto suspension fixtures and attached to the chain conveyor system for continuous processing.

2

Pre-heat Zone

Parts enter the pre-heat zone where temperature is gradually increased to prevent thermal shock and ensure uniform heating.

3

Curing Zone

Main curing zone maintains precise temperature for optimal coating cure, adhesive bonding, or heat treatment processing.

4

Dwell Zone

Extended dwell time at curing temperature ensures complete cross-linking and optimal coating properties.

5

Cool-down Zone

Controlled cooling zone gradually reduces temperature to prevent thermal stress and ensure dimensional stability.

6

Part Unloading

Fully processed parts are unloaded from the suspension system and prepared for final inspection and packaging.

Technical Specifications

Raymond Suspension Chain Oven Equipment is engineered for superior performance, energy efficiency, and reliability, incorporating advanced features inspired by global industry leaders.

| Technical Parameter |

Specification Range |

| Equipment Type |

Continuous Suspension Chain Oven System |

| Oven Length |

10 - 100 meters (customizable) |

| Oven Width |

1 - 6 meters |

| Oven Height |

2 - 8 meters |

| Temperature Range |

80 - 250°C (customizable up to 400°C) |

| Temperature Uniformity |

±3°C throughout the oven chamber |

| Chain Speed |

0.5 - 10 meters/minute (variable) |

| Load Capacity |

50 - 500 kg/meter of chain |

| Heating System |

Natural Gas, LPG, Electric, or Steam |

| Insulation |

High-efficiency mineral wool or ceramic fiber |

| Control System |

Advanced PLC Control (Siemens, Mitsubishi), HMI Touchscreen, SCADA Integration |

| Airflow System |

Forced convection with variable speed fans |

| Heat Recovery |

Integrated heat exchanger systems (optional) |

| Emission Control |

Thermal oxidizer, afterburner, or catalytic oxidizer |

| Safety Features |

Fire suppression, emergency stop, gas leak detection, safety interlocks |

| Automation Level |

Fully Automated Temperature Control, Chain Speed Control, and Process Monitoring |

Solving Customer Pain Points

The Raymond Suspension Chain Oven Equipment is designed to effectively address critical challenges faced by manufacturers requiring efficient thermal processing solutions.

Challenge: Inconsistent Curing and Quality Variations

Our Solution: Precise multi-zone temperature control and uniform heat distribution ensure consistent curing results and eliminate quality variations across all processed parts.

Challenge: High Energy Consumption and Operating Costs

Our Solution: Advanced insulation, heat recovery systems, and optimized burner technology significantly reduce energy consumption and lower operational costs.

Challenge: Limited Production Throughput and Efficiency

Our Solution: Continuous suspension chain processing maximizes throughput and production efficiency while maintaining superior processing quality.

Challenge: Handling Complex Part Geometries and Sizes

Our Solution: Flexible suspension chain system accommodates a wide variety of part sizes, shapes, and weights, providing maximum processing versatility.

Challenge: Environmental Compliance and Emission Control

Our Solution: Integrated emission control systems and thermal oxidizers ensure compliance with environmental regulations and minimize environmental impact.

Challenge: Manual Operation and Process Variability

Our Solution: Fully automated control systems eliminate manual operation variability and ensure consistent, repeatable processing results.

Related Keywords: suspension chain oven, industrial drying equipment, curing oven, conveyor oven, thermal processing, Raymond drying solutions, powder coating oven, paint curing, heat treatment.

Drying equipment is now extremely common application of one type is the use of hot air circulation equipment (there are straight-through drying room and bridge-type drying room).

Drying equipment is the application of the principle of convection heat transfer to the workpiece coating heating and drying, the use of hot air as a carrier, through the convection of heat transfer to the workpiece coating, so that the coating is dried.

The drying equipment uses the hot air circulation drying room features: uniform heating; small temperature difference between the upper and lower temperature; wide adjustable range of drying temperature; easy to use and maintain, etc..

The drying equipment is suitable for coating drying of various workpieces of different sizes and shapes, and the heat source used can be thermal oil, steam, electricity, gas or fuel oil.

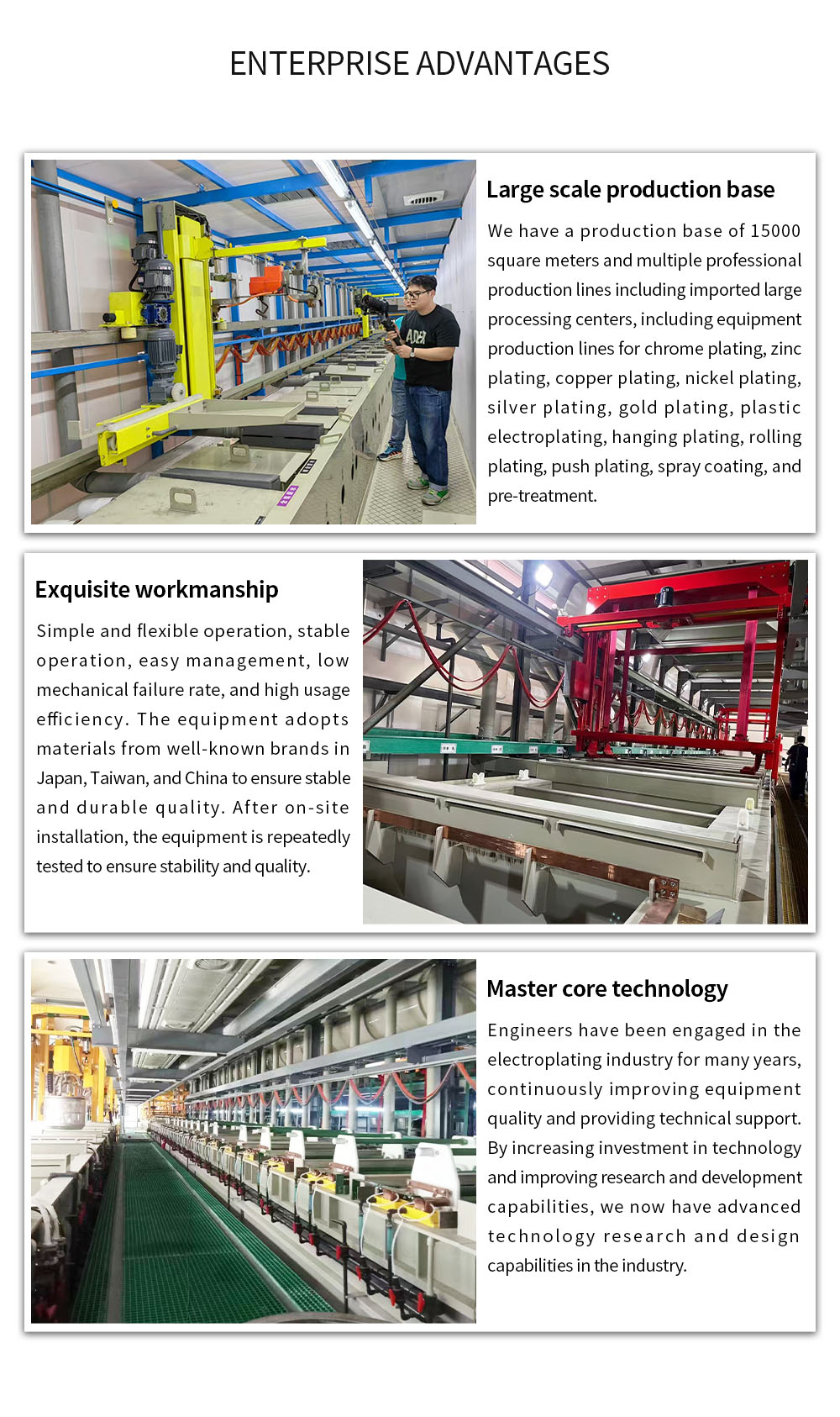

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

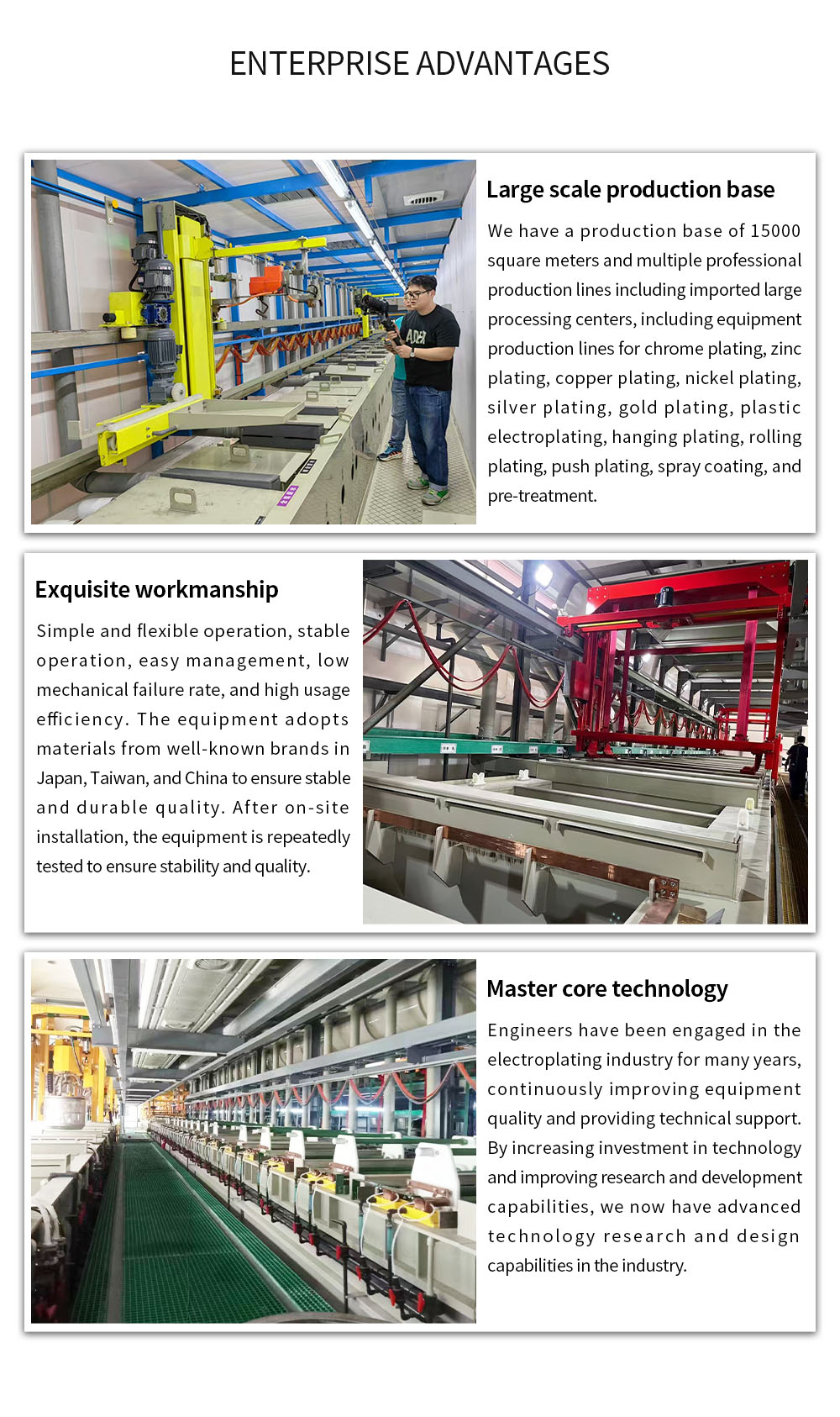

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.