Continuous Plating Equipment Line,Continuous Plating Equipment Manufacturer

Company:

Raymond (Changzhou) Equipment Co., Ltd. | Plating Automation Solution Provider

Keywords:

Continuous Plating Equipment,Continuous Plating Equipment Manufacturer

Raymond (Changzhou) Equipment Co., Ltd. | Plating Automation Solution Provider

Continuous Plating Equipment,Continuous Plating Equipment Manufacturer

High-Volume Automated Electroplating Solutions · Superior Coating Uniformity · Enhanced Process Control

The Raymond Continuous Plating Equipment Line represents a state-of-the-art solution for high-volume, automated electroplating operations across diverse industrial applications. This advanced system is specifically designed to deliver consistent, high-quality metal coatings on a continuous basis, making it indispensable for industries such as electronics manufacturing, automotive components, telecommunications, and precision hardware production. Continuous plating technology offers significant advantages over traditional batch processing, including higher throughput, improved coating uniformity, reduced labor costs, and enhanced process control.

At Raymond, we understand the critical importance of efficiency and quality in modern manufacturing environments. Our continuous plating lines integrate cutting-edge automation technology with precise process control systems to ensure optimal performance and reliability. Featuring advanced material handling, real-time monitoring, and sophisticated chemical management systems, our equipment delivers exceptional coating quality while minimizing operational costs and environmental impact. Drawing on global best practices from leading manufacturers in Europe, USA, Japan, and Korea, Raymond provides comprehensive continuous plating solutions that meet the most demanding production requirements and quality standards. Partner with Raymond for a reliable, high-performance continuous plating solution that enhances your manufacturing capabilities and drives operational excellence.

The Raymond Continuous Plating Equipment Line follows a precisely controlled, multi-stage process designed to deliver consistent, high-quality metal coatings on a continuous basis.

Components are automatically loaded onto the continuous conveyor system and undergo thorough cleaning, including degreasing and surface activation, to ensure optimal coating adhesion.

Parts move through a series of plating tanks where controlled electrical current deposits the desired metal coating. Advanced process control maintains optimal current density, temperature, and chemical composition.

After plating, components pass through multiple rinsing stages to remove residual chemicals and prevent contamination, ensuring coating quality and environmental compliance.

Finally, parts are dried using controlled heating systems and automatically unloaded from the line, ready for inspection or further processing.

Raymond Continuous Plating Equipment Lines are engineered for superior performance, reliability, and adaptability, incorporating advanced features inspired by global industry leaders.

| Technical Parameter | Specification Range |

|---|---|

| Line Type | Fully Automatic Continuous Electroplating System |

| Processing Capacity | 100-2000 parts/hour (depending on part size and coating requirements) |

| Conveyor Speed | Variable, 0.5-10 m/min (adjustable based on coating thickness) |

| Tank Configuration | Modular design, customizable number and size of tanks |

| Control System | Advanced PLC Control (Siemens, Mitsubishi), HMI Interface, SCADA Integration |

| Coating Types | Copper, Nickel, Chrome, Zinc, Gold, Silver, Tin (customizable) |

| Part Size Range | 1mm-500mm (customizable based on application) |

| Coating Thickness | 1-100 µm (adjustable based on requirements) |

| Current Control | Precision rectifiers with digital control and monitoring |

| Temperature Control | ±1°C precision for all process tanks |

| Chemical Management | Automated dosing, circulation, and filtration systems |

| Environmental Controls | Fume extraction, wastewater treatment, chemical recovery |

| Safety Features | Emergency stops, safety interlocks, protective barriers, ventilation systems |

The Raymond Continuous Plating Equipment Line is designed to effectively address critical challenges faced by manufacturers requiring high-volume, consistent electroplating operations.

Our Solution: Our continuous plating systems dramatically increase production capacity, processing components continuously rather than in batches, significantly improving overall throughput and efficiency.

Our Solution: Advanced process control and real-time monitoring ensure consistent coating thickness and quality, eliminating the variations common in manual or semi-automated batch processes.

Our Solution: Fully automated operation reduces the need for manual handling of chemicals and parts, lowering labor costs while improving workplace safety and reducing exposure to hazardous materials.

Our Solution: Integrated control systems with user-friendly interfaces provide comprehensive monitoring and control of all process parameters, making operation simple and reliable even for complex multi-step processes.

Our Solution: Built-in waste treatment and chemical recovery systems ensure compliance with environmental regulations while reducing disposal costs and promoting sustainable manufacturing practices.

Our Solution: Optimized chemical circulation, recovery systems, and precise dosing control minimize chemical consumption and waste, significantly reducing operating costs while maintaining high quality standards.

Continuous plating is a process of electroplating the surface of a continuous strip and is typically used in industries that produce large quantities of metal products. The technology is more productive than traditional plating methods and allows for rapid processing of large quantities.

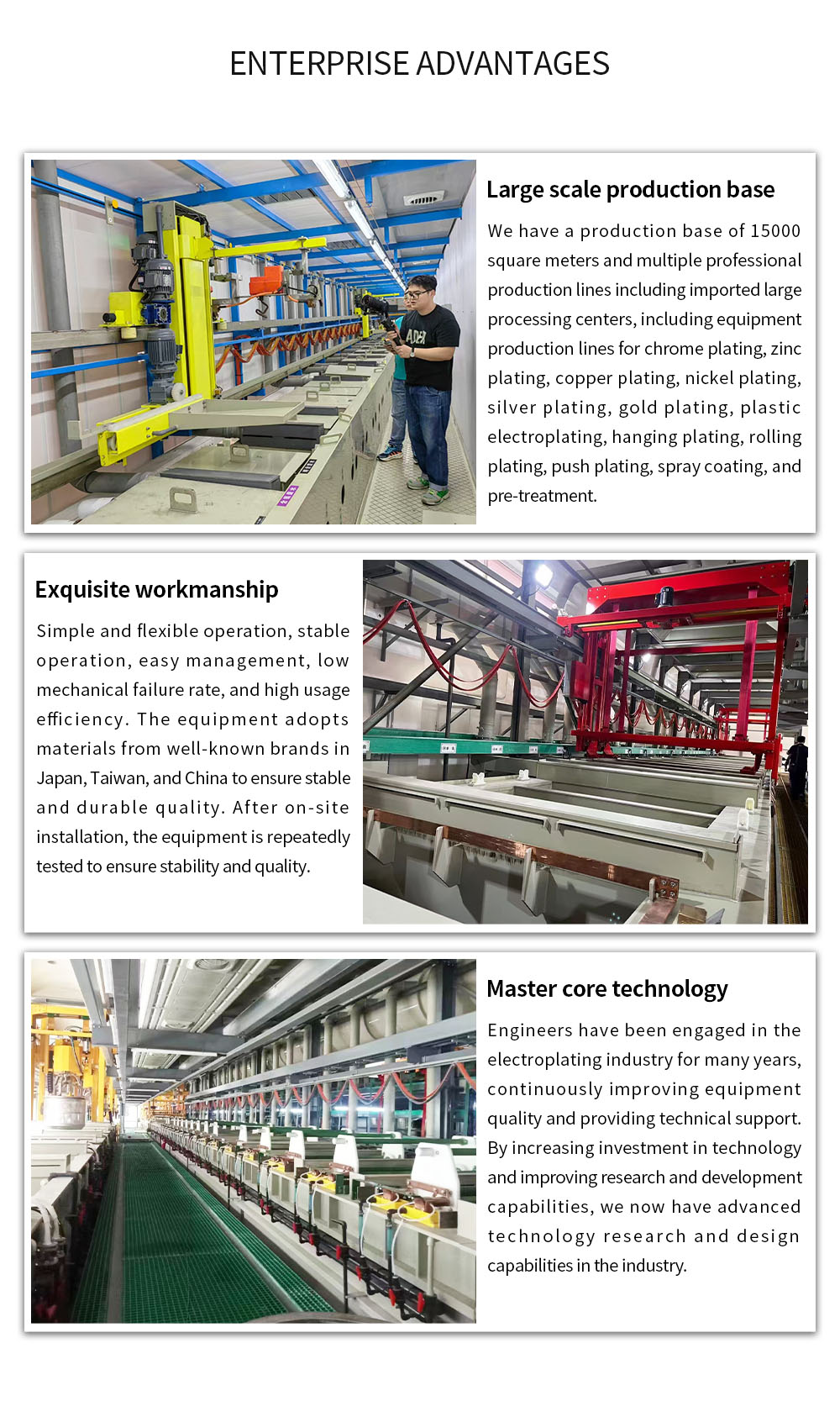

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.