Equipment introduction

Raymond Roller Galvanizing Passivation Equipment - High-Volume Zinc Coating Solutions

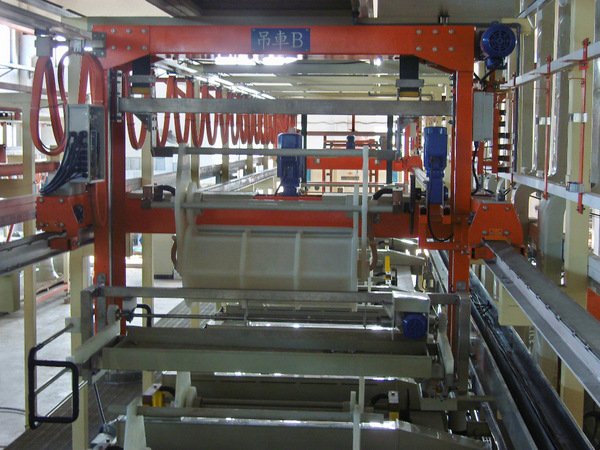

Raymond Roller Galvanizing Passivation Equipment

High-Volume Zinc Coating Solutions · Superior Corrosion Protection · Cost-Effective Processing

Product Introduction

The Raymond Roller Galvanizing Passivation Equipment represents a state-of-the-art solution for high-volume zinc coating applications, specifically designed for small parts, fasteners, and hardware components. This advanced barrel plating system combines the efficiency of roller galvanizing with integrated passivation capabilities, delivering superior corrosion protection while maintaining cost-effectiveness and operational efficiency. Our equipment is engineered to handle large quantities of small parts simultaneously, making it ideal for manufacturers requiring consistent, high-quality zinc coatings at competitive production rates.

At Raymond, we understand the critical importance of reliable corrosion protection in today's demanding industrial environments. Our roller galvanizing passivation equipment integrates cutting-edge automation, precise process control, and robust material handling systems to ensure optimal coating uniformity and performance. The system features advanced barrel design with optimized rotation patterns, intelligent chemical management, and integrated passivation processes that enhance the durability and appearance of zinc coatings. By maximizing throughput while minimizing operational costs, the Raymond Roller Galvanizing Passivation Equipment empowers manufacturers to achieve exceptional surface finishing results, meeting the most stringent quality standards while maintaining competitive pricing and sustainable manufacturing practices.

Core Advantages of Raymond Roller Galvanizing Passivation Equipment

- High-Volume Processing Capability: Our barrel plating systems are designed to handle large quantities of small parts simultaneously, significantly increasing throughput compared to rack plating methods. This makes it ideal for fasteners, screws, bolts, washers, and other small hardware components.

- Superior Corrosion Protection: The combination of zinc coating and integrated passivation treatment provides exceptional corrosion resistance, extending the service life of components in harsh environments and reducing maintenance costs for end users.

- Cost-Effective Operation: Barrel plating offers excellent economies of scale, reducing per-part processing costs while maintaining high quality standards. The automated operation minimizes labor requirements and maximizes resource utilization.

- Uniform Coating Distribution: Advanced barrel design with optimized rotation patterns ensures even zinc distribution across all parts, regardless of their position within the barrel, eliminating issues with uneven coating thickness or bare spots.

- Integrated Passivation Process: Built-in passivation capabilities enhance the appearance and corrosion resistance of zinc coatings, providing options for clear, yellow, or black passivation finishes to meet diverse aesthetic and performance requirements.

- Automated & Intelligent Control: Featuring advanced PLC systems and HMI interfaces, the equipment provides precise control over all process parameters, including current density, rotation speed, chemical concentrations, and treatment times, ensuring consistent quality and repeatability.

- Environmental Compliance: Designed with sustainability in mind, our systems incorporate efficient chemical management, wastewater treatment, and emission control technologies to ensure compliance with environmental regulations while minimizing operational impact.

Process Flow

The Raymond Roller Galvanizing Passivation Equipment follows a comprehensive, multi-stage process designed to deliver optimal zinc coating quality and corrosion protection performance.

1

Loading & Pre-treatment

Small parts are loaded into specially designed barrels and undergo thorough cleaning processes including degreasing, acid pickling, and flux treatment to remove contaminants and prepare surfaces for optimal zinc adhesion.

2

Roller Galvanizing

Parts in rotating barrels are immersed in zinc electrolyte solution. Controlled electrical current facilitates uniform zinc deposition while barrel rotation ensures even coating distribution. Process parameters are continuously monitored and adjusted for optimal results.

3

Passivation Treatment

Following galvanizing, parts undergo passivation treatment to enhance corrosion resistance and appearance. Options include clear, yellow, or black passivation depending on application requirements and aesthetic preferences.

4

Rinsing & Drying

Multiple rinse stages remove residual chemicals, followed by thorough drying using heated air systems. Final inspection ensures coating quality meets specifications for thickness, appearance, and adhesion.

Technical Specifications

Raymond Roller Galvanizing Passivation Equipment is engineered for robust performance and adaptability, with customizable specifications to meet diverse industrial requirements and global quality standards.

| Technical Parameter |

Specification Range |

Notes |

| Equipment Type |

Fully Automatic Barrel Plating Line, Semi-Automatic |

Configurable for various production volumes and automation levels. |

| Control System |

Siemens/Mitsubishi PLC, HMI Touchscreen, SCADA Integration |

Advanced process control, real-time monitoring, data logging, remote diagnostics. |

| Barrel Capacity |

50L - 500L per barrel (customizable) |

Scalable for different part sizes and production volumes. |

| Applicable Parts |

Fasteners, Screws, Bolts, Washers, Small Hardware (1-50mm) |

Optimized for small parts requiring high-volume processing. |

| Zinc Coating Thickness |

5 - 25 µm (adjustable) |

Meets international standards including ASTM B633, ISO 4042, DIN 50961. |

| Production Capacity |

100 - 2000 kg/hour (depending on part size and coating thickness) |

High throughput for cost-effective mass production. |

| Passivation Options |

Clear, Yellow (Chromate), Black, Trivalent Chromium |

Multiple finish options for different applications and regulations. |

| Barrel Material |

Polypropylene (PP), Titanium-lined, Stainless Steel |

Selected for chemical resistance and durability. |

| Tank Material |

PP, PVC, FRP-lined Steel, Stainless Steel (316L) |

Ensures long-term durability and chemical compatibility. |

| Environmental Controls |

Fume Extraction, Wastewater Treatment, Chemical Recovery |

Compliance with environmental regulations (EPA, REACH, RoHS). |

| Energy Efficiency |

High-efficiency Rectifiers, Variable Speed Drives, Heat Recovery |

Optimized for reduced energy consumption and operational costs. |

Solving Customer Pain Points

The Raymond Roller Galvanizing Passivation Equipment is specifically designed to address critical challenges faced by manufacturers in high-volume small parts processing, transforming operational difficulties into competitive advantages.

Challenge: High Per-Part Processing Costs

Our Solution: Barrel plating technology enables simultaneous processing of thousands of small parts, dramatically reducing per-part costs compared to rack plating. Our optimized systems maximize barrel utilization and minimize cycle times for exceptional cost efficiency.

Challenge: Inconsistent Coating Quality on Small Parts

Our Solution: Advanced barrel design with optimized rotation patterns and current distribution ensures uniform zinc coating on all parts. Intelligent process control eliminates variables that cause coating inconsistencies, delivering reliable quality batch after batch.

Challenge: Limited Throughput and Production Bottlenecks

Our Solution: High-capacity barrel systems and automated material handling enable continuous, high-volume production. Our lines are designed for maximum uptime and efficiency, allowing you to meet demanding delivery schedules and increase overall output.

Challenge: Inadequate Corrosion Protection Performance

Our Solution: Integrated passivation treatment enhances the corrosion resistance of zinc coatings, providing superior protection compared to zinc-only finishes. Multiple passivation options allow customization for specific environmental requirements and performance standards.

Challenge: Environmental Compliance and Waste Management

Our Solution: Advanced environmental control systems, including efficient chemical management, wastewater treatment, and emission control, ensure compliance with stringent regulations while minimizing environmental impact and operational costs.

Challenge: Labor-Intensive Operations and Quality Variability

Our Solution: Fully automated operation reduces labor requirements and eliminates human error variables. Intelligent process control and monitoring systems ensure consistent quality while reducing operational complexity and training requirements.

Related Keywords: Roller galvanizing equipment, barrel galvanizing line, zinc plating equipment, passivation equipment, small parts galvanizing, fastener galvanizing, hardware galvanizing, bulk galvanizing, automated barrel plating, corrosion protection zinc, high volume galvanizing, cost effective galvanizing, Raymond galvanizing.

Roller galvanizing passivation equipment is an important equipment in the field of metal surface treatment, which is mainly used for electroplating and passivating metal parts to improve their corrosion resistance, abrasion resistance and aesthetics. The following is a detailed introduction of barrel galvanizing passivation equipment:

I. Equipment Overview

The barrel galvanizing and passivation equipment usually includes the main parts such as barrel plating machine, galvanizing tank, passivation tank, cleaning tank, drying machine and so on. This equipment makes the metal parts uniformly coated with zinc layer in the plating solution by barrel plating, and further improves the corrosion resistance of the plated layer by passivation treatment.

II. Working Principle

1. Roll plating process: The metal parts to be plated are placed on the roller of the roller plating machine, which is filled with a certain amount of plating liquid. With the rotation of the roller, the metal parts are rolled in the plating liquid to achieve uniform plating.

2. Zinc plating process: Zinc ions in the plating solution are deposited on the surface of the metal parts under the action of electric current, forming a dense zinc coating.

3. Passivation process: After galvanizing, the metal parts are fed into the passivation tank, and after contact with the passivation solution, a passivation film is formed on the surface of the plating layer to improve the corrosion resistance of the plating layer.

4. Cleaning and drying: The passivated metal parts are cleaned in the cleaning tank to remove the residual passivation solution on the surface, and then sent to the dryer for drying process.

Large scale production base

Lei Meng Equipment have a production base of 15000 square meters and multiple professional production lines including imported large processing centers,including equipment production lines for chrome plating, zinc plating, copper plating, nickel plating,silver plating, gold plating, plastic electroplating, hanging plating, rolling plating, push plating, spray coating, and pre-treatment.

Exquisite workmanship

Simple and flexible operation, stable operation,easy management,low mechanical failure rate, and high usage efficiency.The equipment adopts materials from well-known brands in Japan,Taiwan and China to ensure stable and durable quality.After on-site installation, the equipment is repeatedly tested to ensure stability and quality.

Master core technology

Engineers have been engaged in the electroplating industry for many years,continuously improving equipment quality and providing technical support.By increasing investment in technology and improving research and development capabilities, we now have advanced technology research and design capabilities in the industry

Lei Meng (Changzhou) Equipment Co. Ltd. is a large-scale equipment manufacturing enterprise.After more than ten years of rapid development, ithas two major production bases in Changzhou and Wuxi, as well as a technology research and development center with a total area of 15000 square meters. lt has multiple professional production lines, including imported large-scale machining centers.